We have been based in Shenzhen for a long time that’s why we have many trustful manufacturing partners in addition to our own manufacturing facility as well as low-cost and high-quality prototyping and manufacturing in Georgia. We have well-established relationships with all our manufacturing partners and they know our standards and design approach ensuring outstanding results for each manufacturing technology with our engineers’ supervision. Manufacturing starts only after lead time and quality requirements(CMF) confirmation.

-

Electronic manufacturing services(EMS):

- • Enclosures and chassis mass production in China, Russia

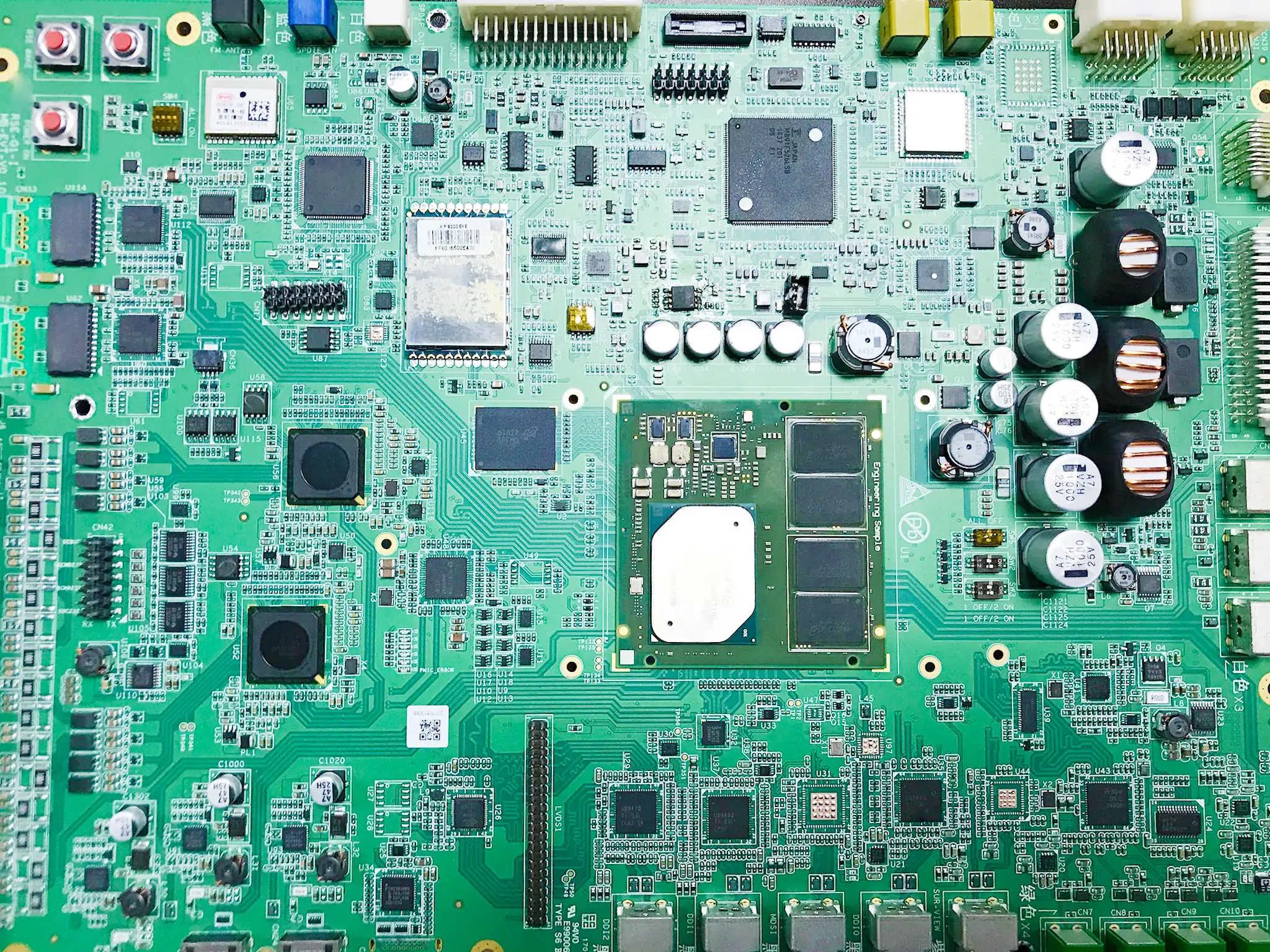

- • PCB and FPC mass production, SMT in China and Russia

- • Manual and automated assembling and testing in China and Russia

Enclosure manufacturing in China is cost-effective and fast as well as normally allows to get access to modern manufacturing equipment. Modern facilities allow the production of parts with different complexity and high accuracy.

- Enclosures and chassis manufacturing capabilities:

- • CNC equipment

- • CNC area 1500 х 3000 mm

- • 0.08 - 0.1 mm - elements location accuracy (higher accuracy upon request)

- • 2.5 mm - minimum hole diameter, smaller holes with laser cut

- • metal cutting and bending

- • electrolytic coating (Zn, Cd); electrolytic coating protecting metals and reducing environment affection to enclosure which lead to longer life time

- • flame spray powdering

- Text and logos application operation:

- • engraving

- • laser engraving

- • 3M film and Oracal film

- • customized films

- Metal finishing operations: Turning works:

- • parts with diameter from 5 mm to 200 mm and length from 5 mm to 700 mm

- • parts with diameter from 100 mm to 500 mm, and length from 200 mm to 800 mm

- • other dimensions upon request

- CNC processing:

- • flat and stepped surfaces, slots, profiles and figures with different volume and geometry, include CNC programming, sizes from 100х100х100 mm to 600х600х600 mm or more upon request.

- • tooth gears, wheels

- EDM processing:

- • Electrical discharge machining for complicated parts

- Other work types:

- • polishing

- • cutting, bending, assembling and welding for metal parts

- • rolled metal cutting up to 40mm thickness

- • forming

- • argon-arc welding corrosion-resist steels and nickel alloys

- • automatic and semi-automatic laser welding

- Electrolytic coating:

- • Zn galvanization, thickness up to 36 um

- • steel parts copper coating

- • chromium plating

- • steel and copper alloys tin-bismuth coating

- • aluminum parts anodizing

- • aluminum parts wear-resisting anodizing Pricing and lead time will be provided upon all technical requirements and drawings analysis finished.

- Commencement of production:

- • EMS partners selection

- • electronic manufacturing services

- • production tools and fixtures manufacturing

- • manufacturing support and management

- • trial run support and analysis Pricing and lead time will be provided upon all technical requirements and drawings analysis finished.

Your advantages:

• our manufacturers base let us choose reliable and robust manufacturer exatly for your product or project;

effective price and short lead time let you save time and get buget optimization;

• fast delivery through well-managed channels let us save time on logistic issues negotiations.

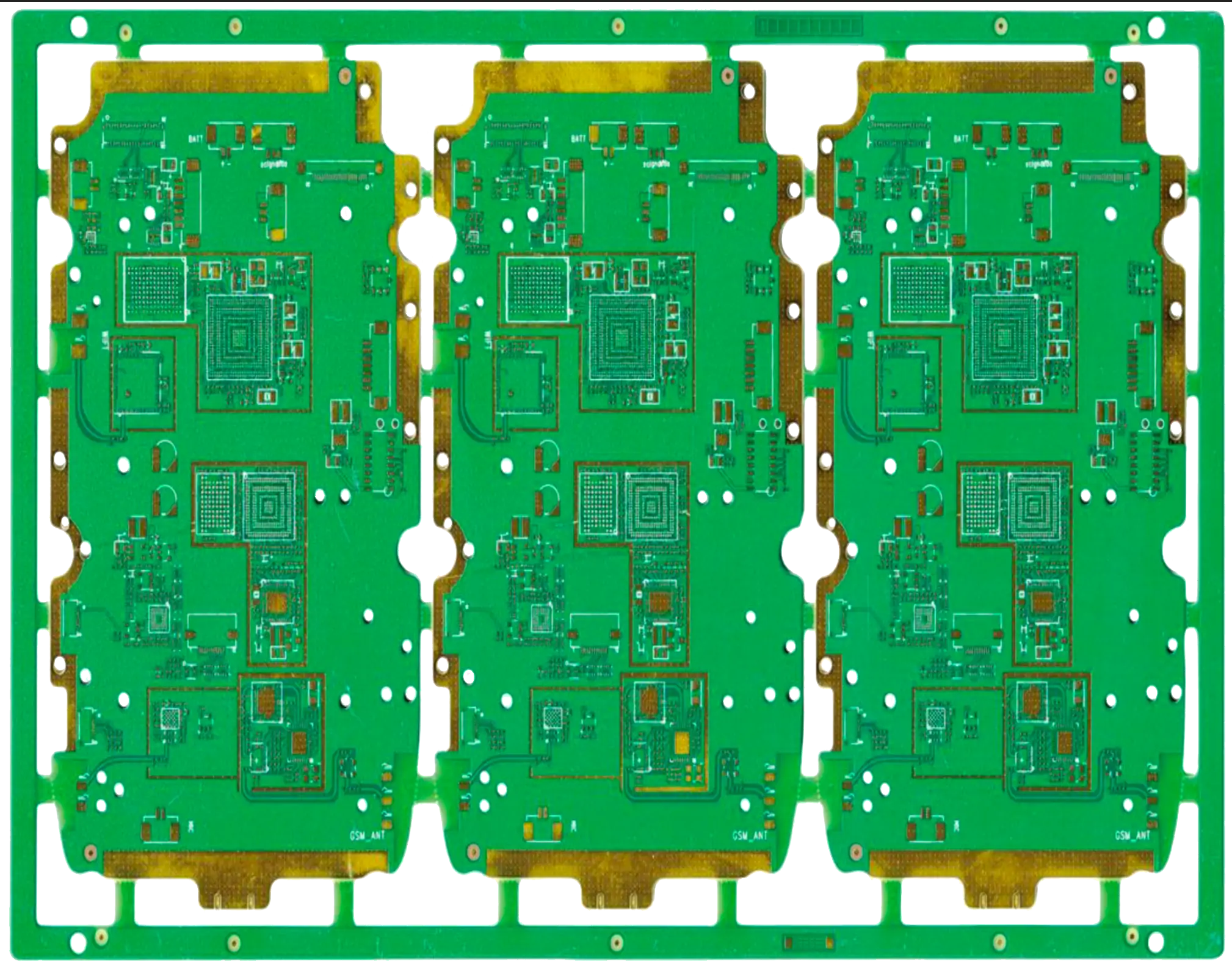

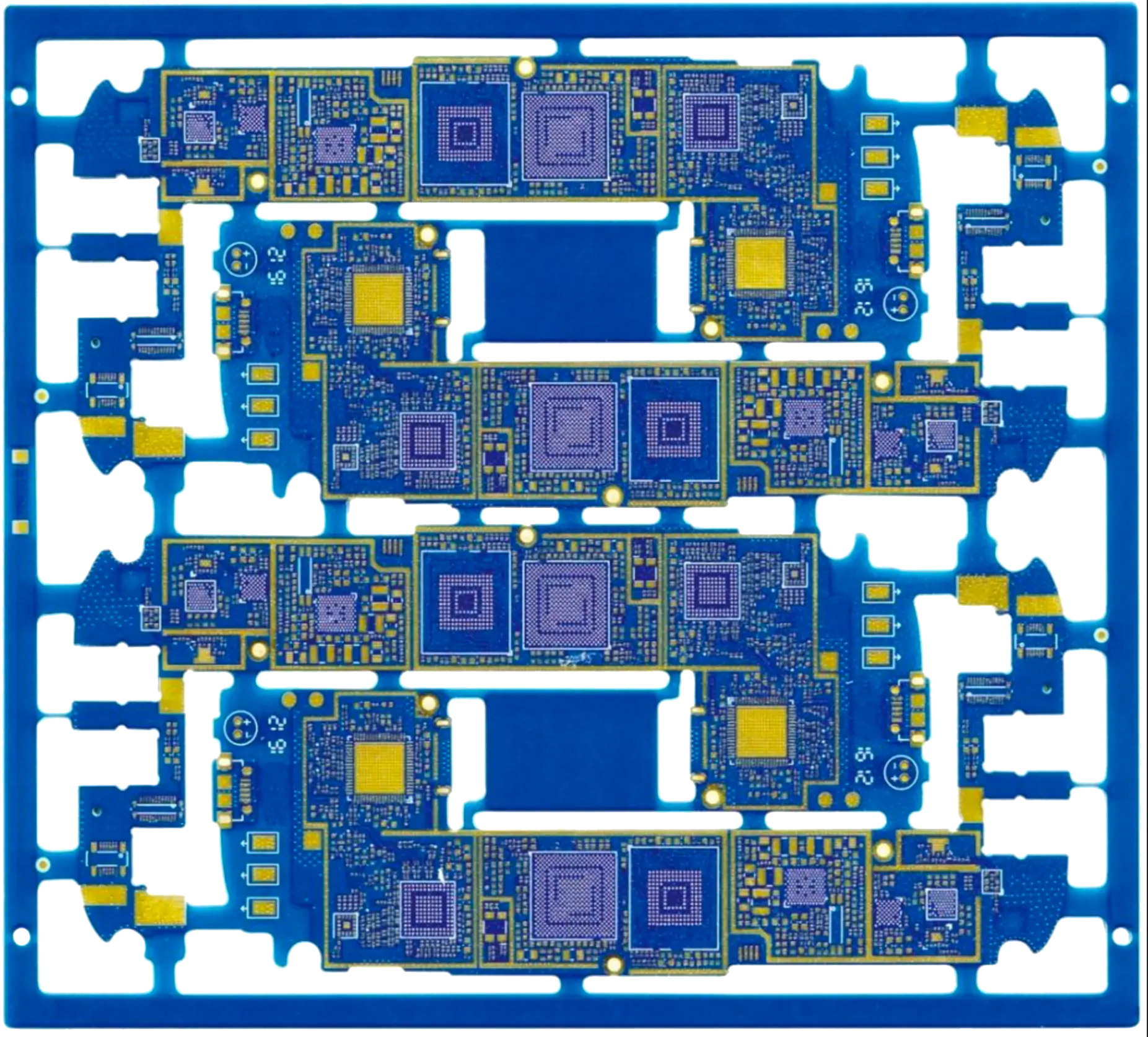

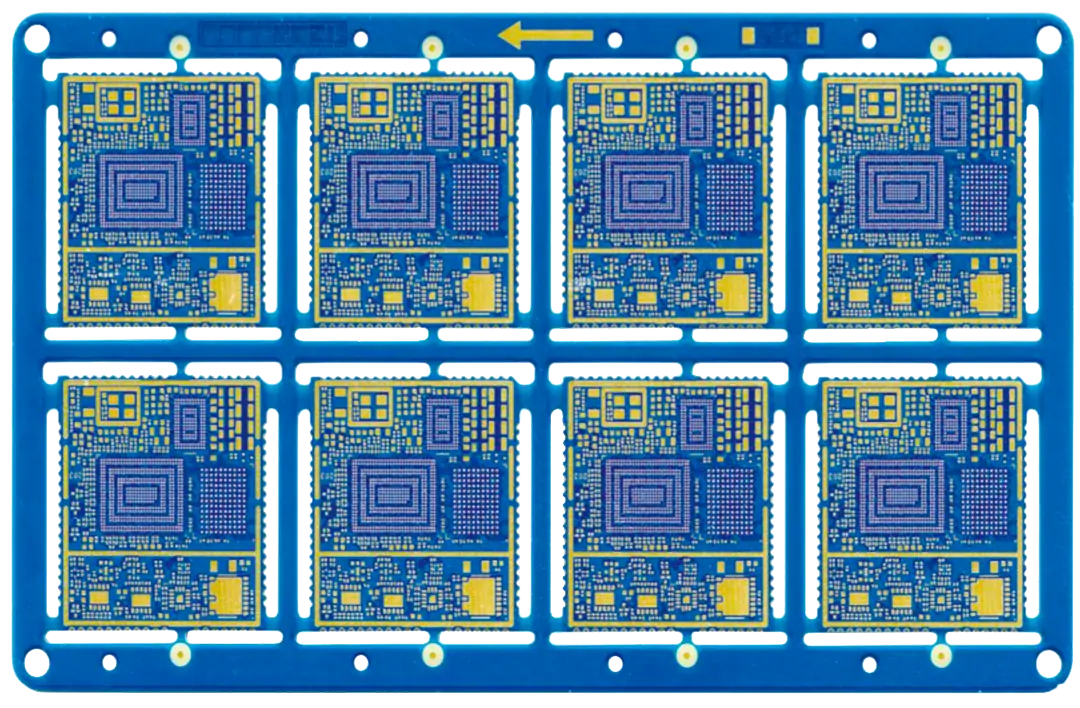

- PCB and FPC manufacturing, SMT

- • 2 layers PCBs

- • multi-layers PCB with holes through board, blind and hidden holes

- • HDI PCB

- • FPC

- • microwave PCB and termal-resistive PCB

- • aluminium PCB Manufacturing options:

- • express manufacturing in China - 5-7 work days 2 layer PCB and 10 days multi-layer PCB

- • mass production batches in China - lead time 2 weeks for any PCB type Pricing and lead time will be provided upon all technical requirements and drawings analysis finished.

Delivery time and logistic terms depend on season and market situation, so we confirming them for each order case y case.